Your cathodic dip coating (KTL) facility is no longer just coating… It is transforming into a smart production station that thinks, analyzes, measures, optimizes, and operates data-driven.

🔹 1️⃣ KTL Bath Measurements & Automatic Chemical Dosing

Continuous analysis of bath chemical parameters ensures automatic dosing, keeping both coating quality and chemical consumption fully under control.

🔹 2️⃣ Up to 80% Savings in Part Masking Costs

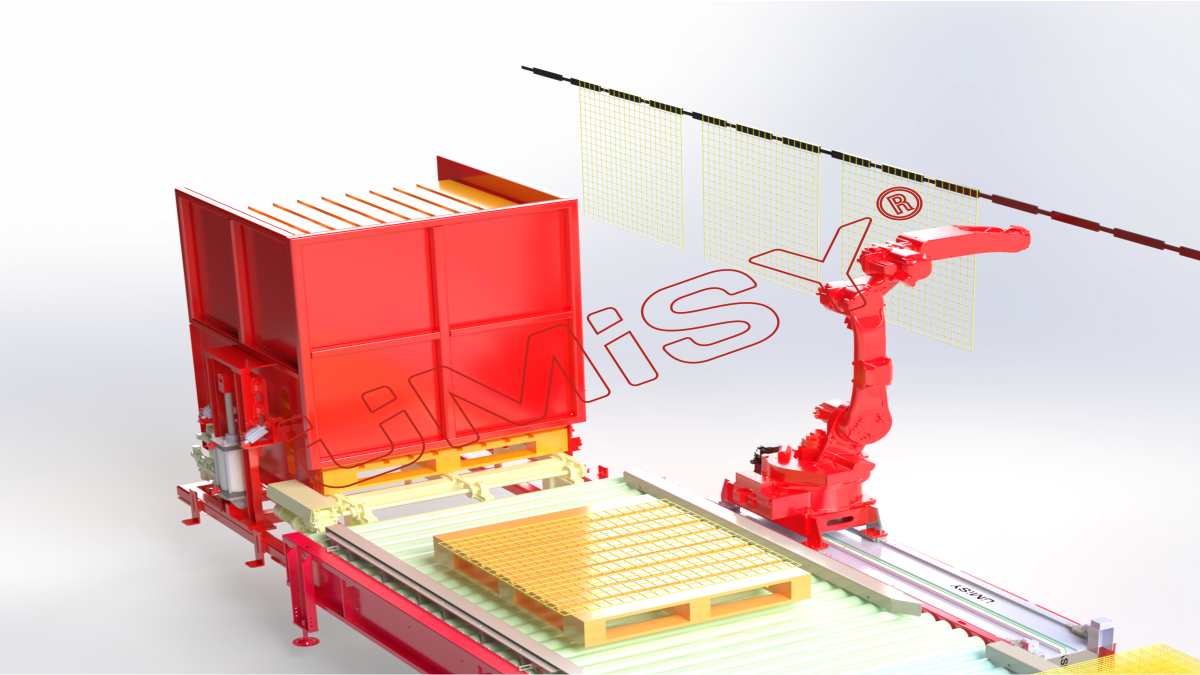

🔹 3️⃣ Prevention of Stains and Labor Loss with Robotic Air Blowing

The pre-oven air-blow station minimizes surface stain marks while drastically reducing labor costs.

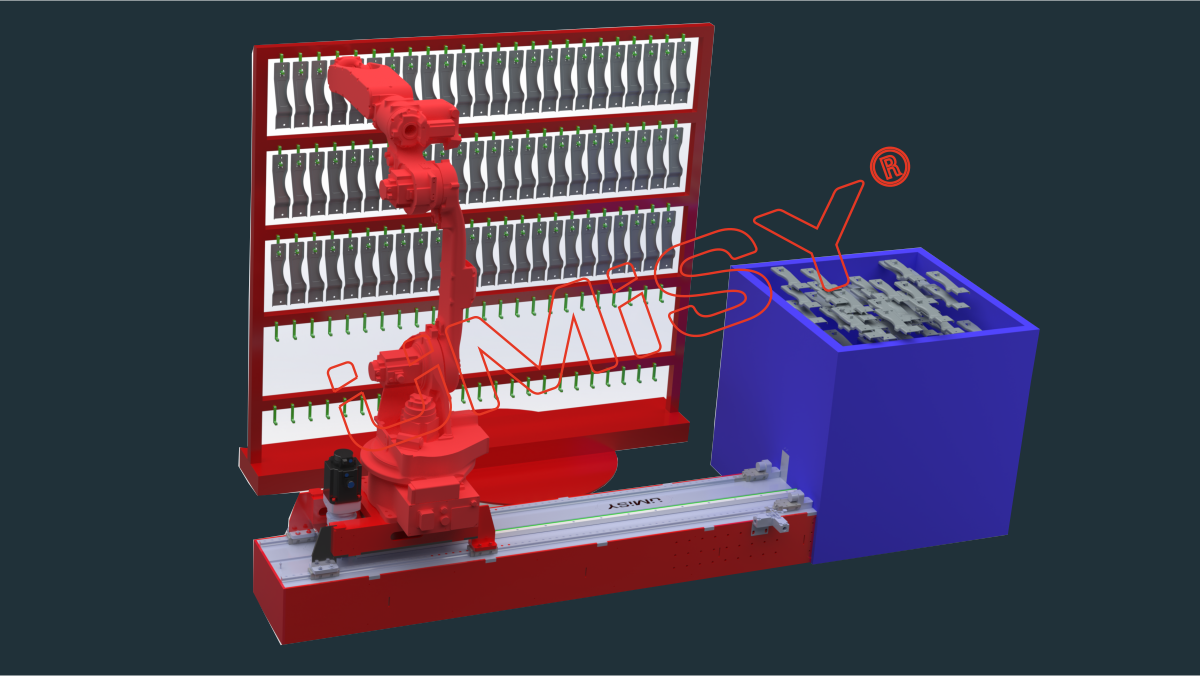

🔹 4️⃣ Mixed Part Hanging & Pick-from-Original inside Baskets

Scattered parts inside baskets are identified by camera and automatically hung by the robot.

After coating, the robot picks the parts from the hanger and places them back into the baskets.

📌 Maximum flexibility with automatic part teaching mode featuring 5,000+ part & hanger memory.

🔹 5️⃣ Pre-Coating & Post-Coating Quality Control — 100% Traceability

Thickness measurement, surface roughness control, arc surface control, coating verification, defect detection and classification are performed through vision-based inspection.

➡ First-class quality and repeatable production.

🔹 6️⃣ Rectifier-Controlled Coating Thickness Management During Process

Real-time thickness feedback enables rectifier control, resulting in higher coating accuracy and reduced material consumption.

🔹 7️⃣ Ümisy KTL Server — Industry 4.0 Traceability Platform

All quality processes, part tracking, process recipes, and production reporting;

📌 can be monitored and managed via ERP / Web / Mobile.

💠 All KTL coating lines are now controlled from a single central system…

Smart, traceable, efficient, and fully automated.